Operation of the machines

The Dense Fluid Degreasing machines are controlled by a Siemens PLC and are fully automated. This control system allows remote maintenance and monitoring

Machines adapted to each environment

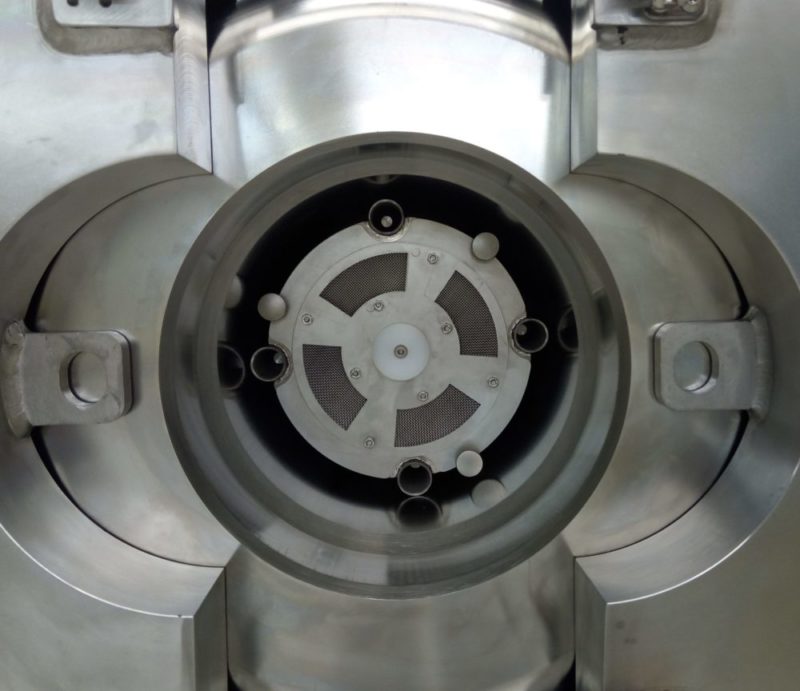

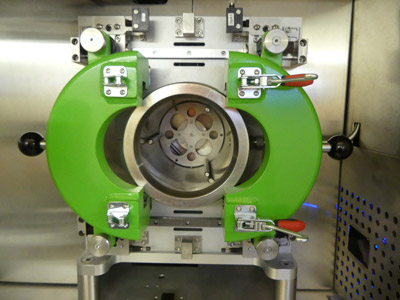

The Dense Fluid Degreasing machines are designed so that the cleaning autoclave(s) are several tens of meters away from the main body of the machine. This machine body can be located in a technical room.

One machine body can operate between 1 and 4 autoclaves, thus increasing production rates.

The autoclave(s) can be located in clean rooms (grey or white) or in different rooms.

[metaslider id="2394"]

Adapted sizing

Dense Fluid Degreasing adapts its autoclave capacity standards according to the production rates to be respected and the size of the parts to be treated. Dense Fluid Degreasing autoclaves range in size from 4L to 550L.

Working pressures can range from 100 to 300 bar.

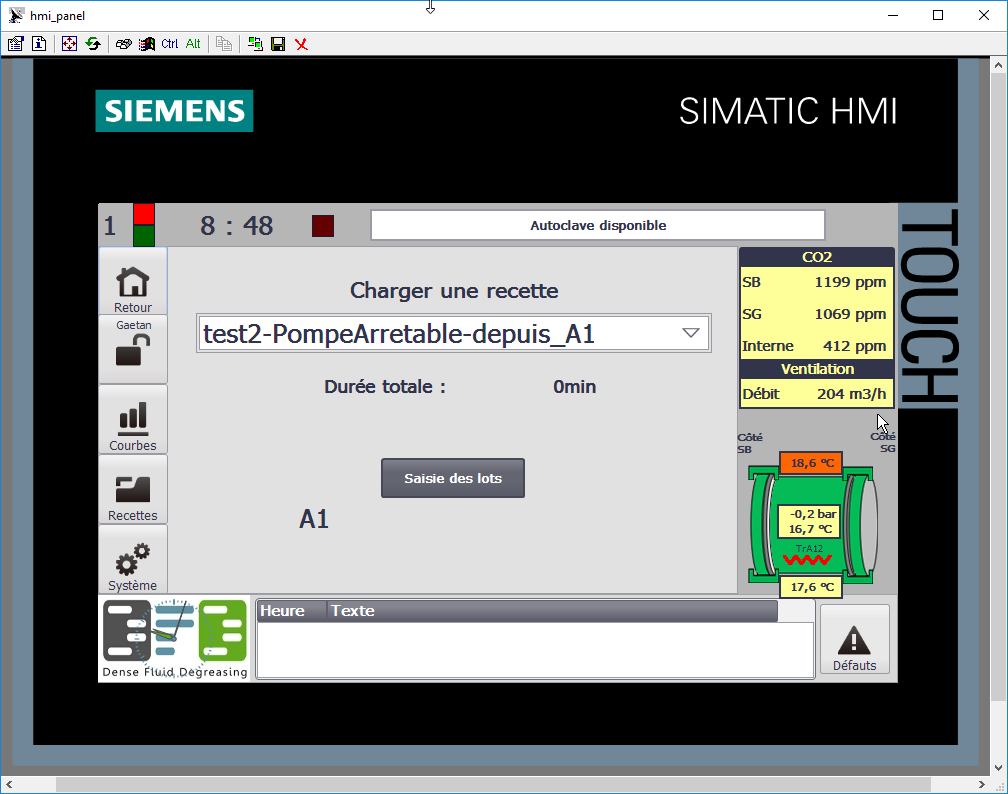

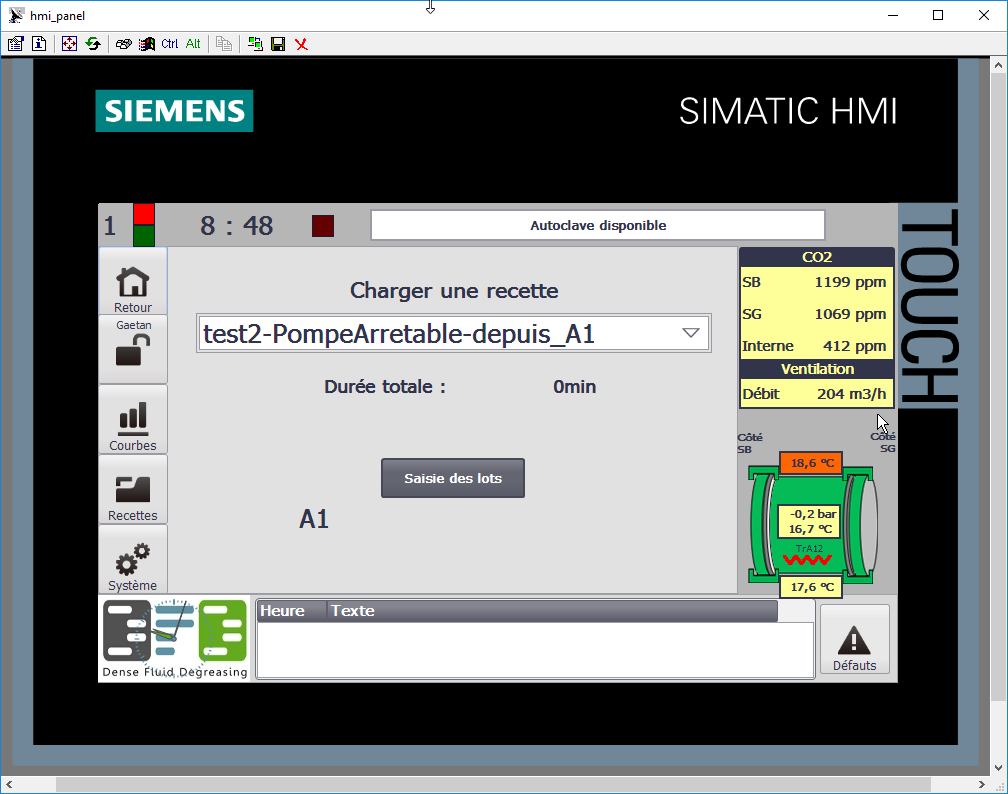

PLC control and command

All Dense Fluid Degreasing machines are equipped with a PLC and Siemens control screen. The touch screen allows the machine to be controlled and maintained either physically or remotely.

![]() Recipe selection and launch (unlimited number of recipes)

Recipe selection and launch (unlimited number of recipes)![]() Modify recipe parameters

Modify recipe parameters![]() Complete monitoring of machine operation

Complete monitoring of machine operation![]() Machine safety management

Machine safety management![]() Predictive maintenance management

Predictive maintenance management![]() Remote control

Remote control![]() Connection to external server possible for retrieval of operating data

Connection to external server possible for retrieval of operating data

Manual or robotic loading

The entire range of Dense Fluid Degreasing machines allows the industrialist to choose between manual or robotic loading.

Discover all the applications of supercritical CO2 cleaning

For medical applications

![]() Machines adapted to cleanroom environments

Machines adapted to cleanroom environments![]() Remote technical unit

Remote technical unit![]() Pre-sterilization of DM

Pre-sterilization of DM

For recycling

![]() Recycling metal chips

Recycling metal chips![]() Extraction of pollutant molecules from a polymer matrix

Extraction of pollutant molecules from a polymer matrix

For mechanical parts

![]() Suitable for all metallic and polymeric materials

Suitable for all metallic and polymeric materials![]() Ideal for complex parts

Ideal for complex parts![]() Removes all residual traces of solvents

Removes all residual traces of solvents

For textiles

![]() Autoclaves for web widths up to 3m

Autoclaves for web widths up to 3m![]() De-sensitizing of textiles in bulk or on reels

De-sensitizing of textiles in bulk or on reels

Find out more

Is supercritical CO2 the only degreasing agent in the machine?

For now, yes. It is important to know that the program of the machine will be adapted to the degreasing of each type of part: washing time, pressure and temperature will be adjusted to achieve the cleaning result, as well as the agitation, oscillation or the addition of ultrasound in the washing autoclave.

In special cases, co-solvents such as water or ethanol, as well as additives such as surfactants or “complexing” agents may be used. We are currently working on the research of bio-sourced and biodegradable additives to complement the action of CO2.

Can CO2 alone remove all types of lubricants?

According to our numerous tests, CO2 alone is as effective on water soluble cutting oils as on mineral oils. However, some remain poorly soluble in CO2. For this reason, our research program continues with the evaluation of surfactant additions.

Do operating personnel need special training to operate a DFD machine?

As with all new equipment, the installation of a DFD machine will be subject to appropriate on-site training. DFD will be able to instruct personnel on maintenance and production processes, as well as on the use of autoclaves and pressure equipment and the operation of the control panel