The best supercritical CO2 cleaning and extraction machines

They trust us

What supercritical CO2 is?

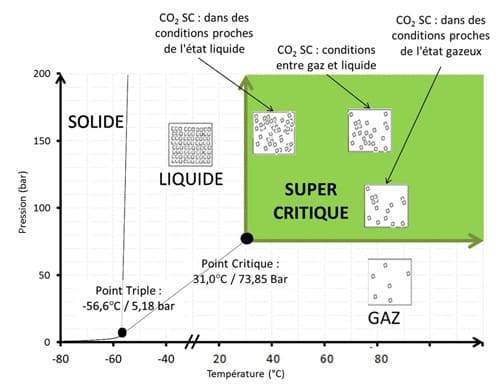

Dense Fluid Degreasing is an equipment manufacturer specializing in supercritical CO2, which is simply carbon dioxide, such as that used to carbonate soft drinks and carbonated water, that is pressurized (minimum 74 Bar) and heated (minimum 31°C).

Once these two parameters are reached, it reaches it supercritical point and enters a phase that is between the liquid and the gas phase.

In this supercritical phase, it acquires the properties of an apolar solvent, which makes this technology the best ecological alternative to chlorinated, fluorinated and petroleum solvents and other laundry detergents.

Today, supercritical CO2 is used in screw-cutting and machining of parts, in medical, food, pharmaceutical, fine chemical, recycling and textile industries.

Designer of supercritical CO2 cleaning and extraction machines

Dense Fluid Degreasing designs, manufactures, assembles and maintains cleaning or extraction machines using supercritical CO2.

These machines are used in the medical device, textile, and recycling industries, mechanical and food industries for degreasing, separating and decontamination of all types of metallic and/or polymeric substrates including textiles or for theextraction of components of interest from biological materials.

Supercritical CO2 cleaning or extraction technology is a real alternative to organic solvent-based processes (perchloroethylene, hexane, dichloromethane, etc.), modified alcohol “A3” processes and leaching processes.

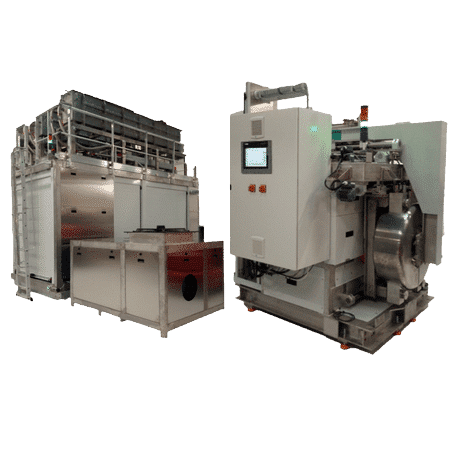

DFD MC 105.3 machine

Perfect for high volume industries

The autoclave block (on the right in the picture) can be more than 50 meters away from its technical unit (on the left in the picture).

This machine is ideal for supporting high production rates. As an option, it can be loaded or unloaded automatically by a robot and start the cleaning cycle automatically.

Autoclave volume: 105 liters

Number of autoclaves: from 1 to 4 autoclaves

Machine DFD MD 7 to 30.3

Perfect for use in clean rooms

The autoclave block is installed in the clean room.

The technical unit can be positioned up to 50 meters away from the cleanroom.

The MD range of machines can be composed of several autoclaves to reach a high production rate.

Autoclave volume : from 7 to 30 liters

Number of autoclaves: from 1 to 4 autoclaves

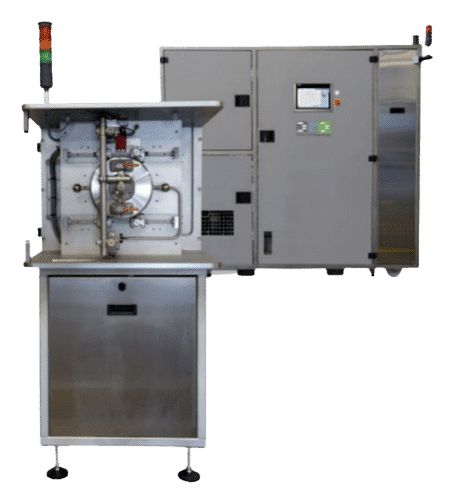

Machine DFD MD6.1 - wall feedthrough

Perfect for demanding industries

Equipped with two doors, the autoclave block is installed across the wall: loading is done in the workshop and unloading on the other side of the wall in the clean room.

Autoclave volume: from 6 liters

Number of autoclaves: from 1 to 4 autoclaves

DFD MC 83.1 machine

Perfect for medium-sized series

Perfect for medium-sized series

This machine is composed of a single block.

Equipped with an 83L autoclave, this is the machine on which Dense Fluid Degreasing teams perform most of the qualification tests.

It is extremely versatile and offers many possibilities.

Autoclave volume: 83 liters

Number of autoclaves: 1 autoclave

DFD MC 4.1 machine

Perfect for small series

This machine is composed of a single block.

No larger than an office cabinet, it can easily be installed in a production workshop.

Autoclave volume: from 4 to 5.6 liters

Number of autoclaves: 1 autoclave

Receive Dense Fluid Degreasing machine data sheets by e-mail!

Dense Fluid Degreasing labelled by Solar Impulse

Dense Fluid Degreasing was awarded the “Solar Impulse Efficient Solution” label in February 2021 following an evaluation by independent experts commissioned by the Solar Impulse Foundation and based on verified standards.

Dense Fluid Degreasing joins the 1000 solutions committed to the ecological transition. As part of this initiative, the Solar Impulse Foundation has selected solutions that meet cost-effective and sustainable standards.

The efficiency of supercritical CO2 for many industries

Supercritical CO2 technology is very complete, meeting many objectives. It is thanks to this specificity that Dense Fluid Degreasing machines can be used to replace traditional polluting processes or for theemergence of new practices.

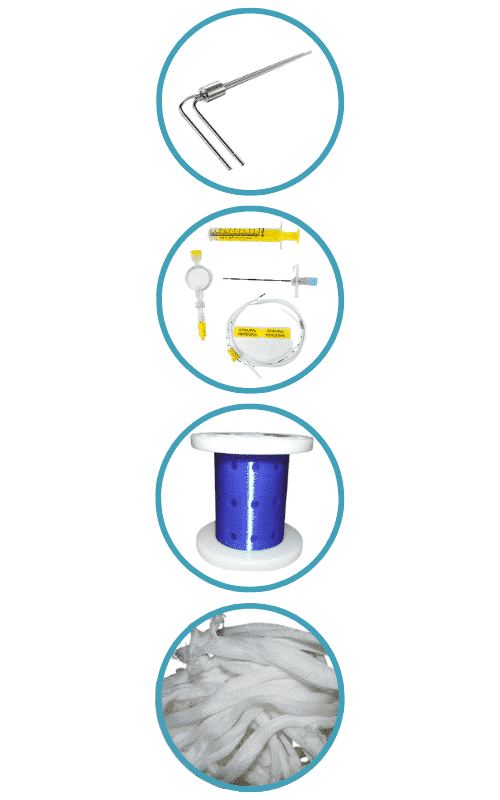

Decontamination of medical devices

Save time in processing your medical devices and gain peace of mind.

Decontamination by supercritical CO2 decontamination is suitable for almost all materials used in the manufacture of medical devices, whether they are made of :

Cleaning and decontamination of medical devices with supercritical CO2 outperforms leach cleaning and Soxhlet processes (ether, hexan…).

They can reduce operating costs by a factor of 4 and reduce processing time by up to a factor of 10.

The advantages of supercritical CO2 supercritical

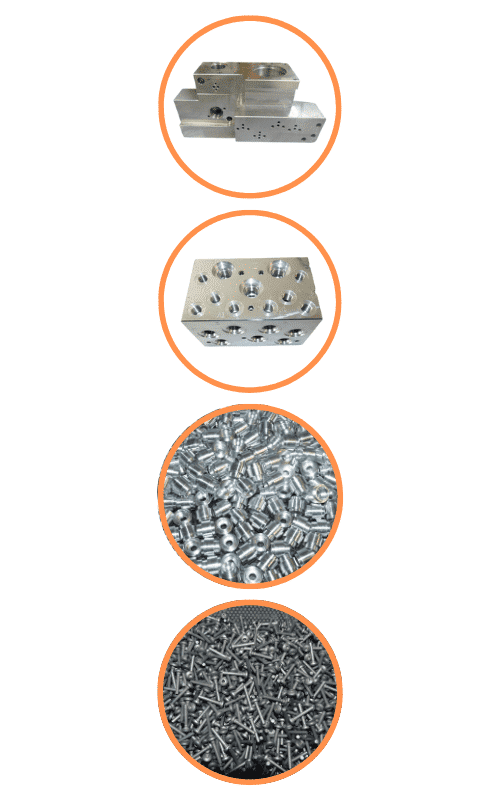

Degreasing and de-crosslinking of machined parts

Degreasing and de-crosslinking of machined or turned parts with supercritical CO2

is a real alternative to the use of organic solvents or “A3” hydrocarbon-based solvents. This process is perfectly adapted to all types of parts, whether they are simple or complex (holes, blind holes, cannulations, complex geometries, etc.).

At low temperature and dry, once the treatment is completed, the parts can be handled without delay.

At the end of the treatment, the CO2 has completely disappeared from the surface of the parts ensuring a surface tension superior to that commonly obtained with traditional solvents.

The extracted particles can be collected dry and ready for recycling.

Cutting or machining oils extracted during the cleaning cycle are collected after a separation step with CO2 and can be reused in your production.

The advantages of supercritical CO2

The special case of additive manufacturing

More and more parts are produced by additive manufacturing processes that must then go through a dewaxing step.

The supercritical CO2

will penetrate all parts of the part to extract the powder residues without risk of solvent or water retention.

This process can be used in the additive manufacturing of metallic or polymeric parts.

Desensitization of new textiles and maintenance of PPE

Reduce your electricity bill, your water consumption and eliminate all pollution due to hydrocarbons.

Supercritical CO2

technology is perfectly adapted to the desensitization of new textiles before coating or functionalization as well as to the maintenance of PPE. The CO2 in its supercritical phase is able to diffuse into all textile fibers and to extract pollutions, be it sizing oils, any greasy pollutions, sweat, etc. trapped in the fibers.

This process can be applied to rolls of fabric as well as to spools of yarn or even to pieces of textile (clothing, wipes, production scraps, etc.)

The supercritical CO2

respects the materials and will not alter the mechanical properties of the textiles. It is compatible with all synthetic and natural materials that can compose a textile or a garment:

The advantages of supercritical CO2

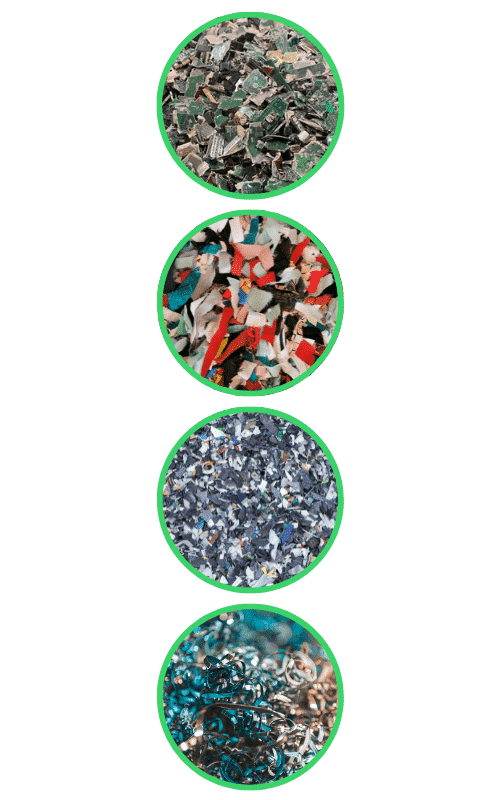

Revalorisation and decontamination of polluted materials

De-pollute and recycle rather than incinerate!

Supercritical CO2

is a process perfectly suited to the recycling industry and the circular economy. It can be used for the decontamination of polluted materials that are currently sent to incineration plants due to the lack of means to decontaminate them.

Whether they are hazardous pollutants such as pesticides, solvent residues trapped in polymers, or plastics contaminated by lubricants or food packaging, supercritical CO2

is capable of decontaminating them.

After treatment, the contaminants are collected in their purest form for destruction in specialized facilities.

The decontaminated materials are completely dry and at room temperature and are then ready for a second life.

The advantages of supercritical CO2 supercritical

The advantages and benefits of supercritical carbon dioxide

100% water saved

Does not use water.

Stable: no solvent treatment, no bath regeneration, no waste, no draining.

Low viscosity and high diffusivity of a gas and high density of a liquid.

100% safe

Non-toxic

Non-flammable

Chemically inert

Non corrosive

100% compatible

Particularly suitable for all part geometries. (tubes, needles, biopolymers, …)

100% healthy

Odourless, colourless

No release of volatile organic compounds

Not classified ATEX

No risk of co-distillation

The advantages and benefits of supercritical carbon dioxide

100% water saved

- Does not use water.

- Stable: no solvent treatment, no bath regeneration, no waste, no draining.

- Low viscosity and high diffusivity of a gas and high density of a liquid.

100% safe

- Non-toxic

- Non-flammable

- Chemically inert

- Non corrosive

100% compatible

- Particularly suitable for all part geometries. (tubes, needles, biopolymers, …)

100% healthy

- Odorless, colorless

- No release of volatile organic compounds

- Not classified ATEX

- No risk of co-distillation

The best alternative to organic solvents

A waterless process to clean up your industry

Ready to evolve your process?

Let's discuss your project

Our sales team will show you the benefits of supercriticalCO2 technology and how it can meet your needs and make your project a success.

Embark on a testing phase

The supercritical CO

2

is a technology that can be adapted to a large number of problems.

To benefit from its full potential, we accompany you in the realization of compatibility validation tests and then optimization tests.

To do this, Dense Fluid Degreasing has a fully automated industrial test bench.

Let's validate your specifications together

SupercriticalCO2 technology is sometimes complex to understand, we help you to define a specification to get the best out of it.

Validation of the process and proposal of a solution adapted to your needs

With a clear specification and validated tests, our technical team is able to carry out an initial study to calculate the cost of acquisition of a Dense Fluid Degreasing machine as well as its operating costs.

Each study is individualized and corresponds exactly to your needs.

Find financing

Our machines are eligible for public grants and subsidies.

Our teams are at your disposal for the search for aid and the preparation of files.

Support and the human touch at the heart of our machines

Because we are convinced that CO2 is a real opportunity that manufacturers must seize to reduce their environmental and health impact, we are doing everything possible to help you learn and master the technology of CO2 and our machines.

Regulatory and safety file

Changing technology can’t be improvised.

This is why the Dense Fluid Degreasing teams are at your side to help you in the daily use of supercriticalCO2 technology and to assist you in all regulatory aspects (IQ, OQ, PQ for medical applications, quality or CSR files, user training, etc.).

Maintenance of your machines

As an equipment manufacturer, Dense Fluid Degreasing offers a complete maintenance program including periodic preventive maintenance, preparation of your equipment for regulatory inspections and remote or physical corrective maintenance.

Our maintenance team is available 7 days a week and 365 days a year.

Innovation at the heart of the industrial approach

Dense Fluid Degreasing innovates by offering eco-designed machines for cleaning and extraction by supercriticalCO2.

At the time of REACH, this green and environmentally friendly process is recognized by several organizations, CETIM, CARSAT, AGENCE DE L’EAU, as a serious substitute for toxic, dangerous or polluting solvents: chlorinated (perchloroethylene, trichloroethylene, dichloromethane), A3 (hydrocarbons, modified alcohols), fluorinated (HFCs, HFEs), laundry detergents,…

In close partnership with the best experts from CEA, CNRS, CETIM and AIR LIQUIDE, Dense Fluid Degreasing’s vocation is to open access to this technology to industrialists to offer them an economic gain, a competitive advantage and an unprecedented sanitary and ecological balance.

CO2 SUPER WHAT?

📢 At Dense Fluid Degreasing we design, manufacture and market cleaning machines with a process you may have heard of before: supercritical CO2. It is simply CO2, the same as that present in sodas and carbonated water, pressurized and heated.

For the more expert among you, you probably know the many benefits of pressurized CO2 🤓. But for those who want to learn more, here is a non-exhaustive list of the benefits of supercritical CO2.