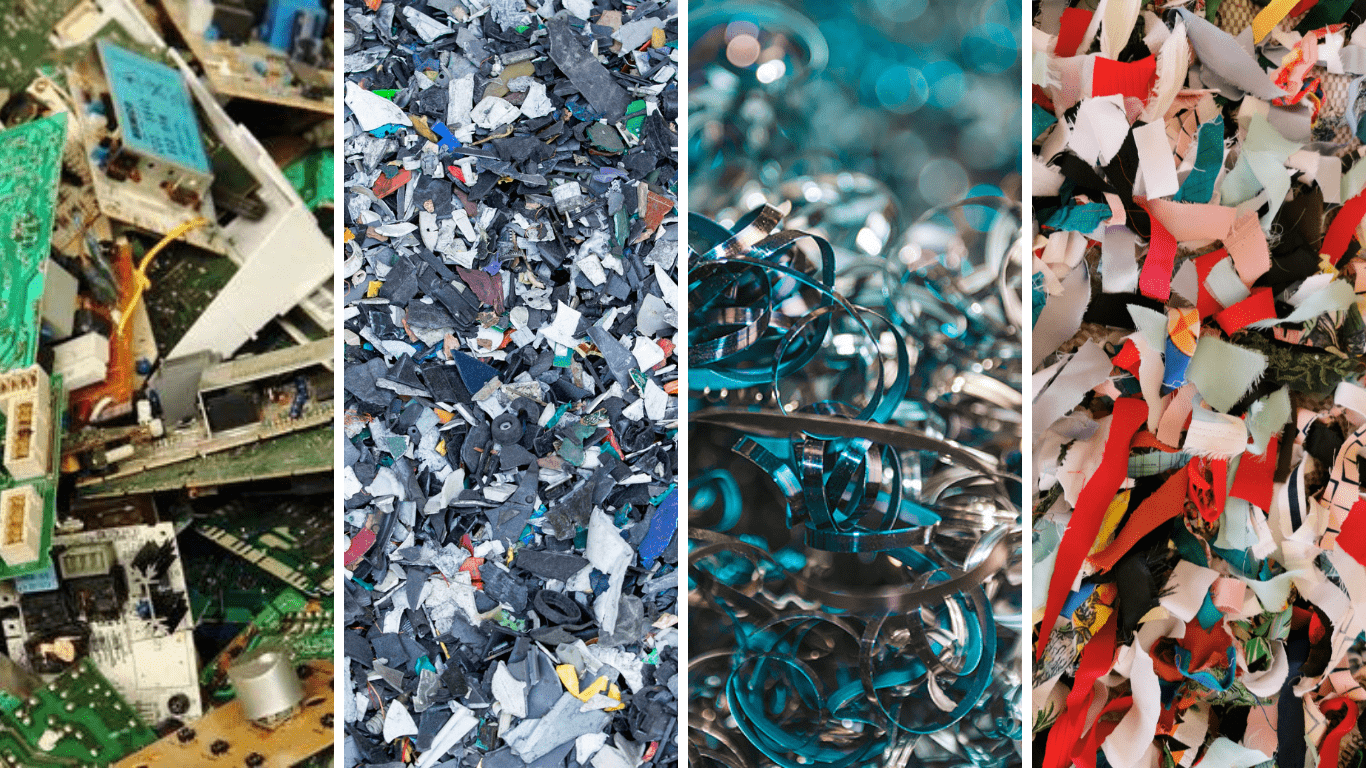

Decontamination and recycling of used materials

There are many applications for supercritical CO2 in recycling. Its solvent and diffusion properties allow it to clean a metal material generated during machining, as well as to extract a contaminant contained in a polymer matrix.

Enhance the value of your rare metal shavings after machining

The advantages of supercritical CO2 for degreasing metal chips

These chips are loaded with oil, and must be cleaned before being remelted.

The use of supercritical CO2 for degreasing machining chips offers many advantages over conventional processes. This process is environmentally friendly:

- No solvents harmful to humans or the environment

- Recovery of dissolved oils and greases with no trace of solvents for reuse in production or destruction in specialized facilities.

Supercritical CO2 allows degreasing the chips while respecting the material (no oxidation).

![]() Residual hydrocarbon content in compliance with ASTM B348 standard

Residual hydrocarbon content in compliance with ASTM B348 standard![]() Dry treatment without water

Dry treatment without water![]() Elimination of polluted aqueous discharges

Elimination of polluted aqueous discharges![]() 50% reduction in energy consumption

50% reduction in energy consumption

![]() Residual hydrocarbon content in compliance with ASTM B348 standard

Residual hydrocarbon content in compliance with ASTM B348 standard![]() Dry treatment without water

Dry treatment without water![]() Elimination of polluted aqueous discharges

Elimination of polluted aqueous discharges![]() 50% reduction in energy consumption

50% reduction in energy consumption

Depolluting plastics for better recycling to recycle them

Extraction of pollutant molecules from a polymer matrix

Polymers often contain numerous additives or molecules/compounds that give them the properties required for the intended application (plasticizers, reinforcements, fillers, colorants, stabilizers, etc.).

They may also contain residues from their synthesis (monomers, solvents, etc.). Thus, in order to recycle the material for new applications, it may be necessary to extract the polluting molecules. The diffusion properties of CO2 allow it to extract them to the core of the material. It is indeed able to diffuse between the polymer chains.

Do you have a project in mind?

Get in touch with our team to talk about it and test supercritical CO2 technology on your parts!

Reusing existing textile materials rather than reproducing raw materials: 3 concrete use cases

Water-free and free of organic solvents

100% environmentally friendly

60% less electricity

Unlimited access to new materials

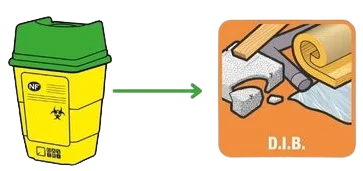

Transforming DASRIA into CIW with supercritical CO2

In its supercritical phase, CO2 becomes a biocide, it will alter the constitution of bacteria and viruses, which will no longer be able to survive.

After treatment, this textile waste could be returned to traditional recycling channels to be transformed into usable secondary primary materials.

Cleaning up absorbent textiles used in industry

In most cases, they are thrown away and destroyed. The quantity of water needed to degrease them and enable them to be used again for industrial purposes would be far too great, generating hydrocarbon pollution in the water.

Supercritical CO2 technology can replace processes using water and detergents, or polluting organic solvents, to degrease and decontaminate these wipes and enable them to be reused in the industrial sector.

Otherwise, instead of simply being incinerated, they can be transformed into recycled secondary materials.

"Hygienize" and decontaminate end-of-life textiles from various sources

Supercritical CO2 can penetrate right to the heart of textile fibers, extracting various pollutants and odors, and killing micro-organisms.

Discover other industrial applications for supercriticalCO2

For the

medical

Decontamination and sterilization of new and used medical devices.

For the

textile

Desensitizing of new textiles and dry care of PPE.

For the mechanics

Degreasing and departiculation of machined parts, from the simplest to the most complex.